BEDFORD, MA, UNITED STATES — Soft Robotics announced today that Boston Conveyor and Automation Corporation (BCA) has joined its Preferred System Integrator program. BCA brings decades of experience to design and manufacture innovative material handling systems for its food and general industry clients.

With Soft Robotics unique food-grade soft gripping, 3D vision, and AI technologies, this partnership will accelerate the growth of robotic automation for even more customers in the food sector.

Soft Robotics Preferred System Integrator Program is an initiative to help integrators win more business with its industry-leading technologies, including the mGrip™ modular gripping system and SoftAI™. SoftAI combined with 3D vision and mGrip, enables machine builders to deliver reliable, high-performance singulated and bulk picking solutions for applications that couldn’t previously be automated due to challenges with delicate, variable, or easily damaged objects. Through this program, integrators will benefit from personalized application support, product training, and growth opportunities with Soft Robotics far-reaching network in the Food & Beverage and Consumer Packaged Goods spaces. The program aims to solve difficult end-user automation problems by connecting members with trusted integrators that have a proven track record of success.

“BCA is proud to be a partner of Soft Robotics,” said Jim Laverdiere, President, and CEO of BCA. “Their innovative approach to gripping technology has allowed us to manipulate and pick customer products that previously were not possible. Soft Robotics commitment to new technology, application support, and testing services, has allowed us to offer our customers more automation and robotic solutions that increase productivity and optimize business efficiency.”

“We are thrilled to have Boston Conveyor & Automation join our Preferred Systems Integrator (PSI) program,” said Harley Green, Director of Business Development at Soft Robotics. “BCA is known for its innovative and high-performance robotic packaging solutions in the food industry where knowledge of food safety regulations and requirements are critical. Having a partner with this expertise will allow for further adoption of Soft Robotics’ systems in the markets that need them the most.”

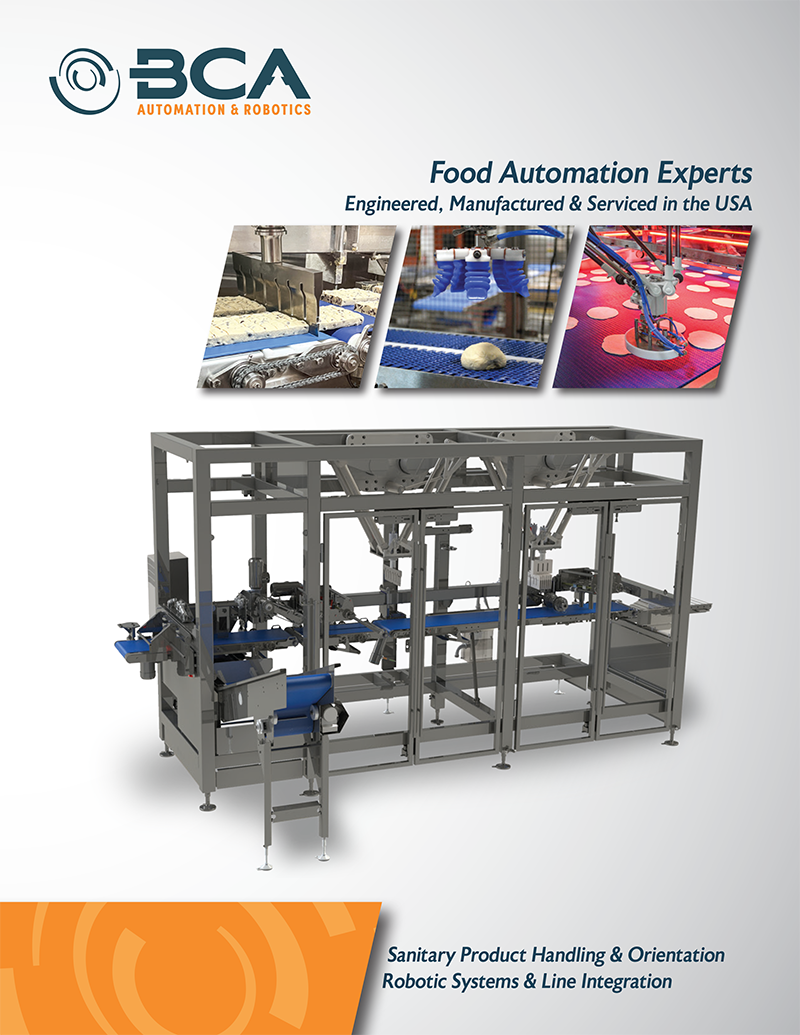

BCA is helping food manufacturers improve their efficiency and throughput by streamlining any process from primary processing to tray-loading bread in a bakery. The company has found great success with pick and place applications for bakery products. Fundamental to their success stems from their significant experience in stainless steel construction and sanitary design. Between their engineering and manufacturing expertise, utilizing Fanuc’s world-class robots and Soft Robotics food-grade mGrip, BCA’s robotic systems will exceed expectations in the most extreme environments. Learn more at https://bostonconveyorandautomation.com/robotic-picking-packing/.

About Soft Robotics

Soft Robotics is an industry-leading and award-winning technology company that designs and builds automated picking solutions using proprietary soft robotic grippers, 3D machine perception, and SoftAI™ artificial intelligence. The company’s transformational robotic automation solutions enable machine builders to solve the hardest piece picking problems in industries like food processing, consumer goods production, and logistics. Learn more at www.SoftRoboticsInc.com.

Soft Robotics is backed by leading venture capital firms and strategic investors that include Calibrate Ventures, Hyperplane Venture Capital, Material Impact, Scale Venture Partners, FANUC, ABB Technology Ventures, Honeywell Ventures, Tekfen Ventures, and Yamaha Motor Co., Ltd.

About Boston Conveyor and Automation Corp.

Boston Conveyor and Automation Corporation is an American company providing automation, robotics, and conveyor systems for the food & beverage, life sciences, and general industry. With in-house engineering and manufacturing, BCA develops and implements automated systems that meet or exceed our customer’s goals for improved productivity and reduced costs.